Tile Coating By FOSROC

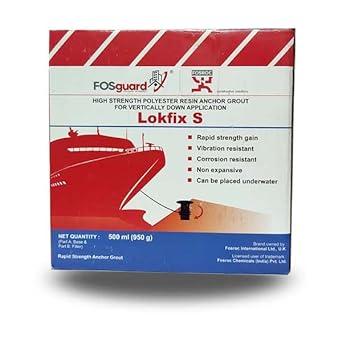

FOSROC LOKFIX S 0.5Ltr - Product Features

- Advantages Rapid strength gain Vibration resistant Corrosion resistant Non expansive Can be placed under water

- Hole preparation and formation Optimum performance of Lokfix requires rough sided, dust free holes. Uses of rotary percussive drills with air or water flushing is recommended. Diamond drilled holes should be under-reamed unless necessary safety factors are incorporated. Cast holes should preferably be inverse dovetail configuration. If parallel sides holes are cast they should be rough to provide adequate keying.

- Bar preparation All bars should preferably be degreased and all flaky rust removed. Mixing A complete pack of resin and catalysed filler should be mixed in one operation. Mixing may be carried out mechanically. When a smooth, even consistency is achieved the grout is ready for use and should be placed well within the gel time of the grout ( See properties). Packs have been designed to produce practical and economic volumes of grout. Do not attempt to mix partial pack components.

- Installation Lokfix polyester resin grout S The grout should be poured steadily into the prepared holes. The anchor bar is then pressed into the hole to the required depth. Slight agitation of the bar will assist in achieving a complete bond. The bar should then be left undisturbed in the required position until the resin is set.

FOSROC CEBEX 100_Pack of 4(0.225kg) - Product Features

- Gaseous expansion system compensates for plastic shrinkage and settlement in properly designed cementitious grout. Reduced water/cement ratio mixes in the grout mix ensures low permeability and long term durability in service.

- Gives grout high fluidity with low water/cement ratio, thus making placement or injection of the grout easy. No metallic iron content to corrode and cause staining or deterioration due to rust expansion in the grout. Composition allows high early strength development in grouts, without the use of chlorides.

- Mixing For best results a mechanically powered grout mixer must be used. For quantities upto 50kg, a slow speed drill fitted with a hig shear paddle is suitable. Large quantities will require a high volume drum mixer. It is essential that machine mixing capacity and labour availability is adequate to enable the grouting operation to be carried out continuously. This may require the use of a holding tank with provision for gentle agitation to maintain fluidity.

- The selected water content should be accurately measured into the mixer. The cement (and sand if required) shall be slowly added to Cebex 100. Mixing shall be continued for 5 minutes, making sure that a smooth even consistency is obtained.

- Cebex 100 is supplied in 225 g packs. For 1 Bag Cement(50kg) add 1 pack Cebex 100 (225grm)

If you have a business establishment in india,

Contact us

to list your business related to any construction categories.Browse by Topic

Construction Events

To Know more about the events about Air Conditioners, Basements, Bathrooms, Bedrooms, Cabinets, Decorating, Design Plans, Doors, Electrical Lightings, Flooring, Home Security, Kitchen, Landscape, Painting, Plumbing, Fixtures and many more..

648

648 780

780